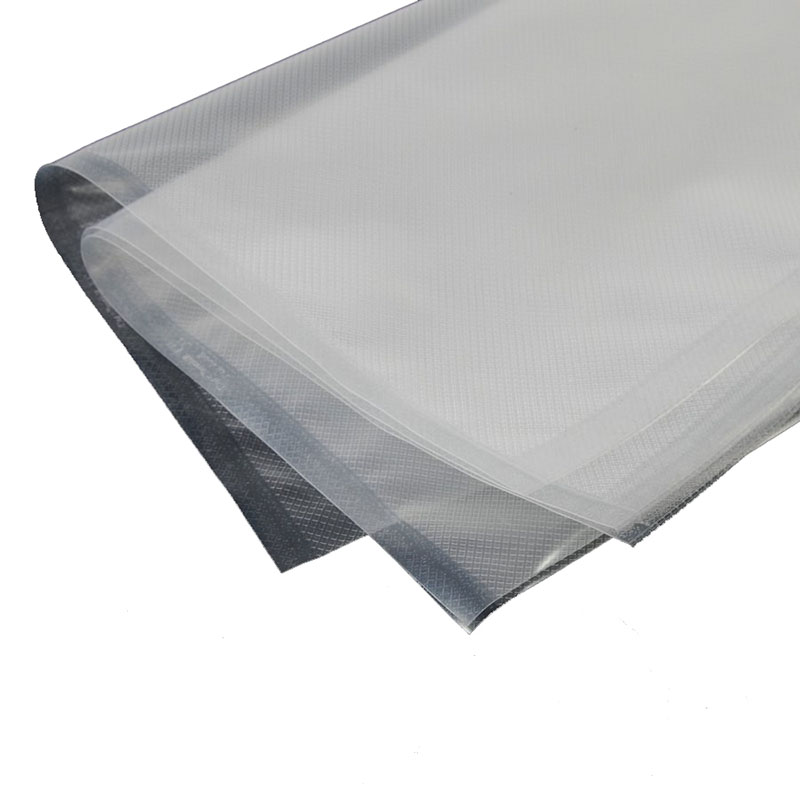

Vacuum Food Sealer Bag

We are one of few packaging manufacturers who have a certified clean room facility. All our food contact products are produced in our certified 100K clean room and adhere to the most stringent quality checks.

Conventional vacuum food bag & sous vide bags are produced through lamination, this means chemical agents are used to bond the different layers of material together to create the bag. Over time and especially when heated there is a chance the chemical agents in the laminated material may be released. Our vacuum bags are co-extruded meaning there is no chemical agents added. All our vacuum bags are FDA certified food safe. We offer our bags in either ready to use sachets or in rolls.

The most usual color for our bread bags is transparent, although other colors are also possible. Printing on the bags can be up to 8 colors with either flexo or rotogravure printing. Both the bag sizes and printing designs are usually custom made according to our customer’s specification.

Our vacuum food bag & sous vide bags are favored by central kitchens and the F&B industry who will use them to prepare, package, portion and distribute their food to retail stores and restaurants etc. Suitable for Food storage and sous vide cooking. Designed for used with vacuum machines such as FoodSaver Series. Material: 5 layer co-extrusion PA/PE Size custom made to your specifications. BPA free. Non-toxic bags. Food grade and FDA approved. FDA/SGS/EN1935/2004/ISO9001/QS certified 100K clean room production environment. Bag style customisable per client’s request. Available in ready to use open bags or in rolls.

Material: 5 layers co-extrusion PA/PP (Food Grade)

Size: Customize – OEM

Thickness: 0.08mm

MOQ: 10,000 pcs

Options:

- Material options include PAPE, PA/PP & EVOH